what is RFID?

TAG: What is it. - RFID labels.

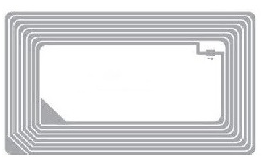

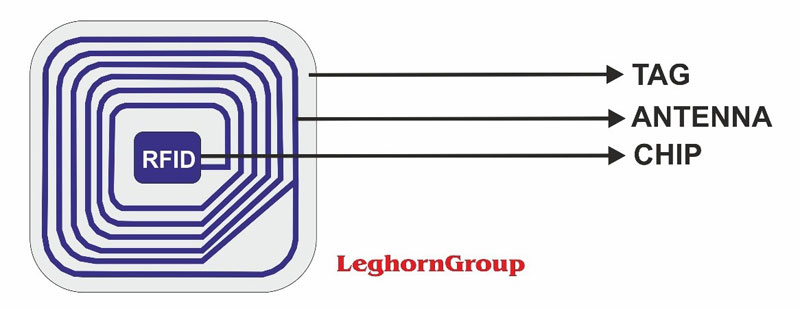

Basic components of an RFID tag are:

- Microchip

- This component contains the label-specific data.

- It can store information such as unique codes, product handling, production data, storage point.

- Antenna

- The antenna wirelessly transmits data contained in the microchip.

- It allows two-way communication, when activated by a radio frequency signal emitted by an RFID reader.

- Support

- Normally it is a label made of adhesive paper, or plastic.

Types of TAGs:

Passive TAGS

- They have no energy of their own

- Short reading distance

- Inability to integrate auxiliary

sensors

LOW COST TAG

Semi-passive TAGS

- They are helped to “awaken” thanks to their own

energy - Long reading distance

- Can integrate auxiliary sensors

MEDIUM COST

Active TAGS

- They have their own energy

- Long reading distance

- Can integrate auxiliary

sensors

HIGH COST

Is RFID the same as NFC?

The answer is NO!

NFC is a subset of RFID technology and offers more limited capabilities compared to RFID.

It operates at very short distances—up to 10 cm—beyond which communication with the reader is not possible.

NFC also enables two-way communication between the reader and the NFC tag.

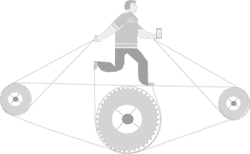

How Passive RFID Works

ACTIVE RFID

How it works technically

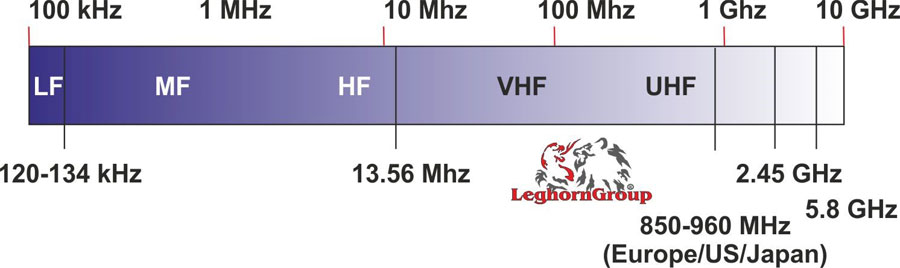

What are the frequencies used in RFID?

RFID systems use various frequencies, which can be classified as:

– low frequencies (LF, between 125 and 134 kHz)

– high frequencies (HF, around 13 MHz)

– very high frequencies (UHF, between 860 and 960 MHz)

– microwave (over 2.45 GHz)